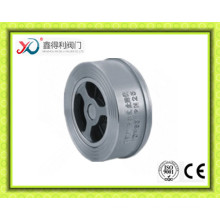

Lifting Check Valve Spool & Sleeve Assly

| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW |

| Delivery Time: | 10 Days |

| Packaging: | Vacuum Packing |

|---|---|

| Productivity: | 500 pieces a day |

| Brand: | DAYUE |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Dongguan |

| Certificate: | IOS9001 |

| Port: | Yantian |

Basic Info

Model No.: DAYUE069

Click on the follow link to find out more information: https://www.dayuechn.com/valve-components/

Company Info

- Company Name: Dayue Precision Technology

- Representative: Hou Jun

- Product/Service: Mold Components , Grinding & Honing , Carbide Tools , Ceramic parts , Eccentric shafts , CNC Machining

- Capital (Million US $): 10,000,000RMB

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 1% - 10%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 7

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No.2 Jiatianheng Rd.1, Xiniubei, Dalang Town, Dongguan, Guangdong, China.

- Contact Person: Ms. lexie

- Tel: +86-13412420118

Email to this supplier

Premium Related Products

Other Products

Hot Products

Brass Stop Cock (a. 0153)3-Way Brass Manifold with Handle for Water (a. 0183)Brass Gas Vent Relief Safety Valve (a. 0192)Brass Filter Valve with Plastic Core or Brass Core (a. 0195)3/8"-1/2"Female X Male Brass Mini Ball Valve (a. 0129)F X M Cw617n Electric Brass Ball Valve (a. 0196)Brass Pressure Reducing Valve with Watch (a. 0208)Floating Type Steam Trap ValveFlat Plate Class300 Gate ValveForged Steel Extended Body Gate ValveForged Steel Lift Check ValveAPI Casting Steel Globe ValveWorm Gear Operation Plug ValveAPI 603 Gate ValveTop Entry Ball Valve (SUGO NO. 502)Metal Seat Electric Butterfly Valve (MB Series)